Precision of New Hampton Automotive

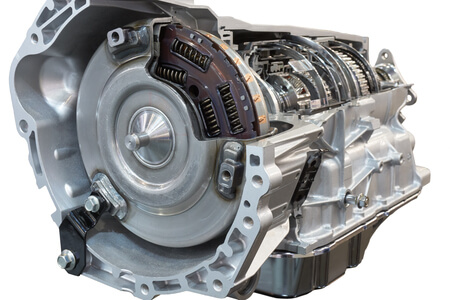

Quality Automotive Torque Converters

Why Choose Precision of New Hampton for Automotive Torque Converters?

We have been in the industry for over 35 years and you can tell experience matters! Our main plant has grown to 500,000 square feet, with over 1 million converters in stock. Every step in the rebuild process has been put under a magnifying glass to ensure our customers are getting the highest quality products in the industry. Give us a call to hear more!

We are Innovation!

Balancing that is computer controlled, lock-up testing, leak testing, and quality assurance in our run-outs are all part of our quality control standards.

Application To Transmission

They bolt in with no modifications. Motor plate applications may require a spacer kit. Saving you time and money in installation and effort.

Custom Builds

These torque converters are built per your indicated specifications. Units will normally ship no later than one day after placement of order.

Give us a call to Place an Order: 1-800-654-1220

Our Automotive Torque Converters Always Include

Every torque converter is manufactured with new parts that are equal or higher quality than most of those in standard OEM’s.

We are currently producing over 1500 UNITS PER LINE PER DAY! Our diverse supply of torque converter cores allows Precision to provide quick turn around for the customer that doesn't have the core or needs to ship their unit in for rebuild and return. It is a rare situation that we can't supply a core for your needs.

Precision of New Hampton uses only the highest quality lining with the best co-efficiency of friction that matches the mating surfaces. Our unique bonding procedures provide 100% adhesion. Our torque converters are meticulously and professionally manufactured.

Computer controlled lock-up testing, leak testing, and quality assurance in our run outs are all part of our quality control standards.

Converter Balancing: Whether a converter is welded or furnace brazed, your converter NEEDS to be REBALANCED INSIDE and OUT for peak efficiency and to eliminate any vibration.

Most competitors do not even have the balancing equipment!

Precision of New Hampton is the ONLY COMPANY IN THE INDUSTRY that balances each individual part to within 1 gram.

Balancing issues can cause metal fatigue, efficiency loss, horsepower loss and inevitable early torque converter failure.

Customize and Modifications

Our Inventory is one of the biggest in the world!

Lets do bueiness togther!

We will build to your exact specifications

Customer satisfaction for us is number 1!Millions Of Cores In Stock!

We will be able to build you anything!

Advanced CNC Machines for Precision of New Hampton Specifications

We have a team of CNC engineers with over 200 years of combined experienceThe engineers behind the CNC (Computer Numerical Control) machines are dedicated to build schematics that can be replicated over and over to rule out any human error when machining parts. Each torque converter gets converted into pure numbers that way we can adjust and do the math to make something perfect.