We Do It All

We have been in the industry for over 35 years and you can tell experience matters! Matching experience with the drive to make our own parts we will exceed expectations. Our main plant has grown to 500,000 square feet, with over 1 million converters in stock. Every step in the rebuild process has been put under a magnifying glass to ensure our customers are getting the highest quality products in the industry. Give us a call to hear more!

Every Type & Size

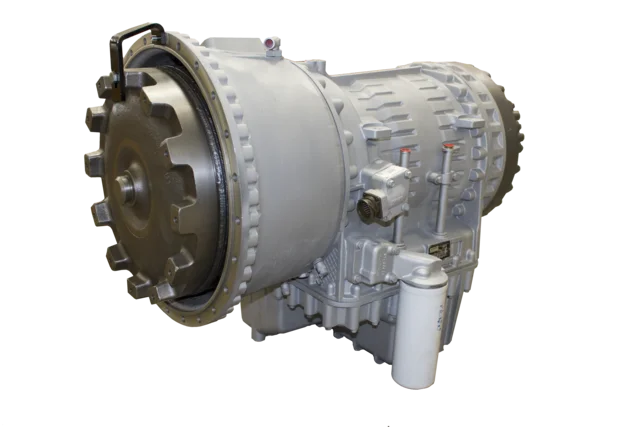

From material handeling to articulated truck size, welded / sealed, or bolt-together—we can handle them all! We build 1,500 units a day for all types of transmissions.

Capability & Knowledge

To fix the most heavily damaged cores; saving our customers thousands of dollars versus the cost of a new torque converter. We fix what others can’t or won’t!

Fully Equipped Machine Shop

With 16 5-axis lathes, 8 5-axis mills, wire EDM machines, graphite EDM, surface grinder, broaching machine, and heated / furnace brazing, more parts can be fabricated in-house. Our turn-around time is 24 to 48 hours!

Give us a call to Place an Order: 1-800-654-1220

Off-Highway Torque Converters

Billet Custom Parts

The billet cover option is standard for all high performance racing converters and is available as an option for some industrial converters.

Torque Converter Balancing

Whether a converter is welded or furnace brazed, your converter NEEDS to be REBALANCED INSIDE and OUT for peak efficiency and to eliminate any vibration. Most competitors do not even have the balancing equipment!

Precision of New Hampton, Inc. is the ONLY COMPANY IN THE INDUSTRY that balances each individual part to within 1 gram. Balancing issues can cause metal fatigue, efficiency loss, horsepower loss and inevitable early torque converter failure.

Furnace Brazing

Our furnace brazing process completely laminates the turbine and the impeller. This effectively makes your converter one piece, leaving no weak link in your converter to cause a failure. The majority of our competitors weld their converters.

Welding only holds at individual spots, creating a converter that is only as strong as its weakest weld. Furthermore, welding changes the flow throughout the converter by causing cavitation or disruption of flow.

Furnace brazing ensures that there is no flexing of the turbine, no more cavitation or disruption of flow, providing more raw power to your tires. Every tab on a Precision torque converter is of equal strength to any other; all due to the furnace brazing process. A welded converter is only as strong as the weakest weld.

Bottom Line: Welding in the turbine process results in a DIRECT LOSS of EFFICIENCY and HORSEPOWER. Is that what you want for you or your customers?

Hardened Turbine Splines

Most competitor's performance converters come with turbine splines that have a hardness of 0. This rating is just inadequate for the application; and, too often, the result ...

IMMEDIATE CONVERTER FAILURE

Precision uses hardened turbine splines, virtually eliminating a major reason for torque converter failure. 90% of the time it happens right at the starting line. The input splines on the transmission have a hardness rating of 35 on the Rockwell scale of C; the mismatch with the 0 rating on the turbine shears the splines right off of the turbine. Another step that the competition skips - a cost cut that will only cost you in the long run.

High Performance Stators

Precision installs a redesigned stator to give you maximum torque multiplication equaling more horsepower.

Trade Secrets

Precision performs so many other unique applications while building converters. The competitors DON’T and consequently, Precision has patented the process on these special practices.

Those features combined with UNBEATABLE CUSTOMER SERVICE are what makes our racing converters the ONLY CHOICE for your industrial application.

Torque Converter Reinforcing

Precision of New Hampton wants your converter to last as long, if not LONGER than the rest of your ride. Bearing that in mind, another option offered is converter reinforcement. An EXTRA metal reinforcement plate is added to the converter. This plate in conjunction with our anti-balloon plate, gives a transmission with Precision’s torque converter that "extra edge" in preventing ballooning of the converter under the most EXTREME conditions.

Multi-Roller Sprag

A multi-roller sprag is a high performance replacement for the regular sprag that is more often installed. It encapsulates all parts tighter with VERY strict quality control. The main motivation for a multi-roller sprag is greater durability and increased vehicle response time. The multi-roller sprag does not contribute to any loss of power, a spragless converter does.

Friction Disc System

Precision’s Triple Disc Clutch is the ultimate option when building a converter that will TRULY stand above the rest.

The Triple Disc retains lockup for efficiency without durability issues and will virtually ELIMINATE SLIPPAGE by providing a vastly increased clutch surface.

Did you know that slippage is one of the main causes of transmission failure? That’s right, every time the clutch slips, the clutch surface becomes HOTTER, eventually causing the surface to glaze over and become VERY SLIPPERY and VERY BRITTLE. When the clutch surface becomes more and more slippery, the clutch slips EVEN MORE. The eventual brittleness leads to tiny pieces breaking away—and where do they go?

That's right. The clutch debris passes through to the transmission and eventually, with enough pieces, your transmission will break down, causing costly repairs. Precision’s TRIPLE DISC CLUTCH, while giving you optimal performance, SAVES YOUR TRANSMISSION as well!

Racing High Performance

Partnering ONLY with the Best

Call To Place An Order!Our engineers are trained and qualified to take your industrial application and rebuild it to a higher standard. Through persistence and experience we will find or manufacture parts to have your equipment performing like never before. We have access to the latest technology and most expensive rebuild equipment available, give us a call to request more information. We would be happy to prove it!